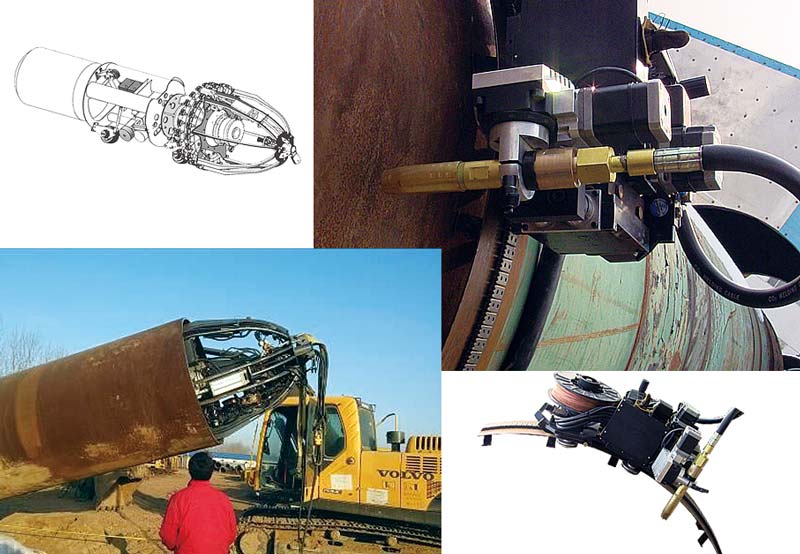

全自动管道焊机

全自动管道焊机 | Automatic pipe external welding

- 产品优势 | Product Advantage

- “传送导气电缆技术”

- “双导杆焊接单元外部支撑技术”

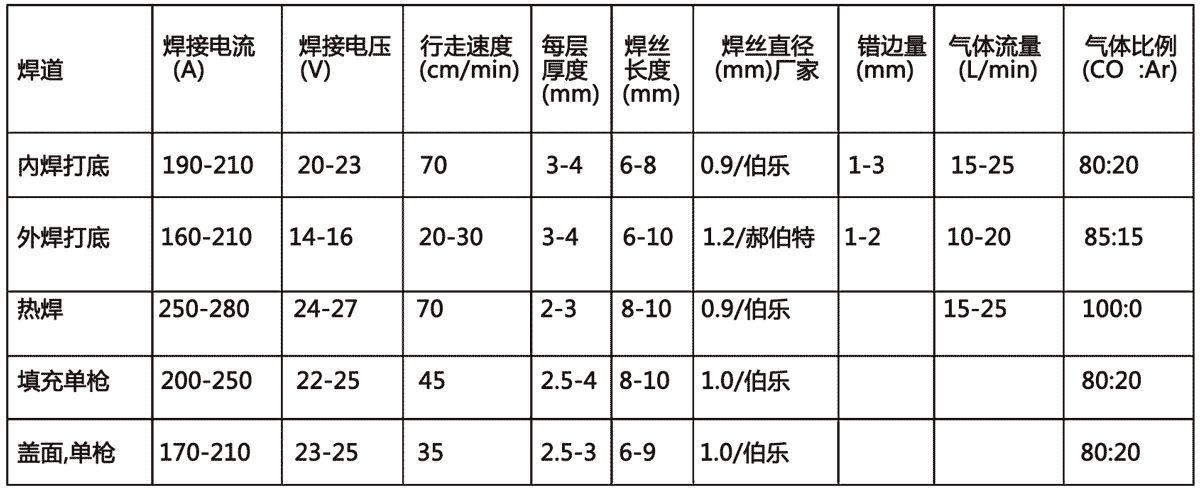

- “6焊接回路一体化电源”

- "based on the hollow cylinder transfer gas leading cable technology"

Within each welder welding unit gas leading cable, through the tubular when tight cylinder structure of the hollow shaft, concentrated to machine cage outside the center of the pre-tightening device. When welding, welding Unit were migrated gas cable pointer centered on tubular cylinder cylinder core micro reciprocating 36 degrees, guide gas inside the cylinder core cable of the wear rate is extremely low, effectively save the cost of spare parts. - "double guide rod welding unit external support technology"

New welding unit to remove welding units on the market the motion of the head, on the outside of the welding unit installed double guide rod support cylinder mechanism, welding head positioning precision high reliability; using Compressed air as the support power, effectively save the shielding gas, welding units and quicker in daily maintenance - "Welding power supply circuit integration, 6"

(1), digital controlled soft start, solve the welding arc and the lap joint impact to power generation equipment, etc.

(2), pulse welding, improve the forming of weld bead.

(3), reduce the external start, such as the burning time delay control links.

(2)、脉冲焊接,改善内焊焊道的成型。

(3)、减少外部启动,反烧延时等控制环节。

北京安捷伟达科技有限公司拥有全部使用条款和隐私条款。版权所有,保留一切权利。 备案编号:京ICP备19034245号